Why are the costs of carabiners made using different processes so different?

When customers inquire about carabiners, they often notice a price difference. Therefore, understanding the logic behind the costs of carabiners made using different processes can help you choose the solution that best suits your brand positioning and budget.

1.Wire forming

Wire forming is formed by bending aluminum rods directly by machine, then polishing and surface treating. This method is highly efficient and suitable for mass production, offering affordable unit prices. It is suitable for small, non-load-bearing products such as keychains, promotional gifts, luggage accessories, EDC, and outdoor accessories for hiking, camping, and cycling. However, the material limits its structural strength, and the design constraints restrict its shape.

Watch this video to explain how wire bending is used: https://www.youtube.com/watch?v=K9DBlYbr4GI

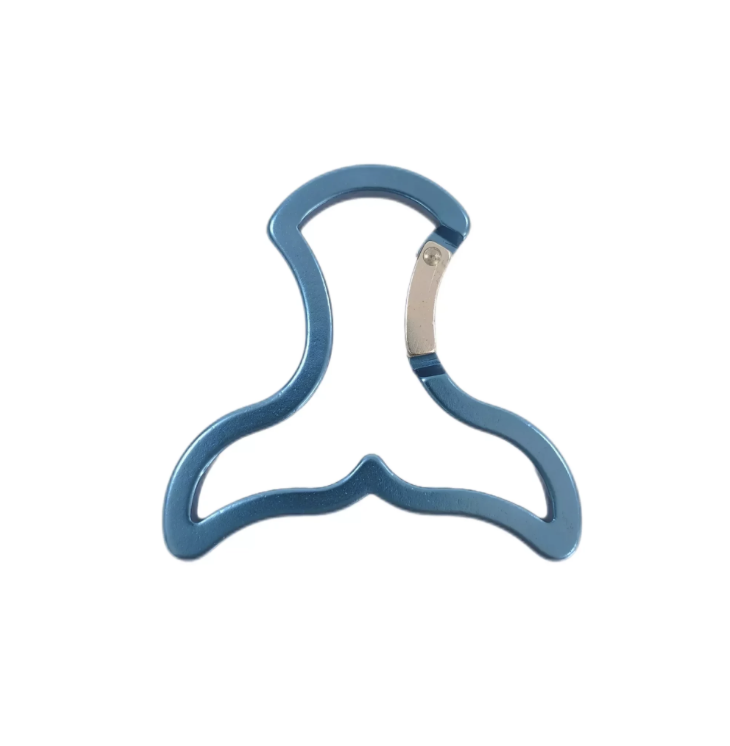

2. Cutting and Forming

Cutting and forming are cut into the desired cross-section using pre-fabricated molds. Compared to wire, profiles offer a wider variety of shapes and a more refined appearance, meeting the diverse customization needs of brands. They offer consistent shapes and are suitable for customers who require custom graphics. However, due to the high mold costs and unit price, they are suitable for customers with a stable repeat order volume.

Watch this video to learn more about cutting and forming using custom molds: Updating…

You can also learn more about our carabiner production process in our article: https://www.samhe.com/how-do-we-produce-aluminum-carabiners-our-carabiner-production

3. Drop Forging

Drop forging is the use of high-tonnage machines to stamp aluminum, making the internal structure of the metal denser and significantly improving its strength. Customers choose this type of product for high-tension and load-bearing applications, as well as when they demand superior quality and appearance. Its durability makes it suitable for safety equipment or high-end brands. However, this leads to higher manufacturing costs and an MOQ requirement.

Watch this video to learn how to stamp aluminum using a machine: https://www.youtube.com/shorts/pIpJKW9LEBw

Why the price difference?

1. Material Utilization: Wire casting reduces waste, while forging requires more raw material.

2. Mold Cost: Profiles and forging processes require custom molds, while wire materials rarely require complex molds.

3. Labor and Equipment: Forging requires high-tonnage equipment and manual adjustment, which naturally results in higher costs.

4. Application Scenarios: Wire materials are sufficient for non-load-bearing gifts, but forging is required for safety equipment.

Advice for Customers

- Gift companies & promotional brands & outdoor products & fashion luggage brands → Choose wire materials, which are reasonably priced and suitable for large-scale production.

- Brands requiring custom company logos or requiring specific shapes → Profile materials are more suitable, offering both aesthetic appeal and a customized look.

- Rock climbing, industrial safety, or high-end equipment brands → Choose forging to ensure strength and safety.

Different crafts aren’t simply determined by price; they are directly related to customer needs, usage scenarios, and brand positioning. Understanding these differences will help you make more accurate decisions when purchasing carabiners.

So, if you want to choose the right carabiner—whether wire forming for affordable gifts, cutting and forming for customized shapes, or drop forging for safety and premium gear—contact us today at info@samhe.com. We will recommend the most cost-effective and brand-appropriate solution based on your application, budget, and market positioning. Let’s work together to create the perfect carabiner for your brand.